Description

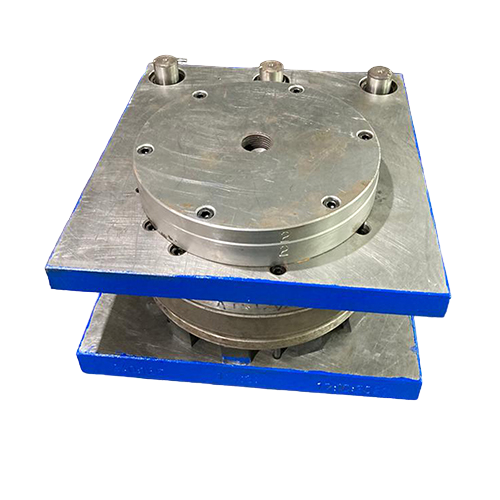

A stamping die, also known as a press tool or simply a die, is a specialized tool used in metalworking processes such as stamping, punching, blanking, bending, and forming. It is designed to shape or cut sheet metal or other materials into specific shapes or profiles with precision and consistency. Stamping dies are essential components in various manufacturing industries, including automotive, aerospace, electronics, and appliances. Here are some key aspects of stamping dies:

Our range is customized on the following :

Material: Mild Steel(Die)

Pattern Type: Plain

Tolerance: 0.01 mm

Mould Runner: Hot Runner

Usage: Used In Automotive Industry

Components :

A stamping die typically consists of two main components: the upper section, known as the punch, and the lower section, called the die. The punch is mounted on the press ram and delivers the force necessary to shape or cut the material, while the die is fixed on the press bed and provides the desired shape or profile. The die may contain cavities, holes, or contours that correspond to the final product's specifications.

Materials :

Stamping dies are typically made from hardened tool steels, such as carbon steel, alloy steel, or tool steel grades like D2 or A2. These materials offer high hardness, wear resistance, and toughness, enabling the dies to withstand the forces and pressures involved in the stamping process. In some cases, specialized coatings or surface treatments may be applied to enhance the die's performance and longevity.

Manufacturing Process :

Stamping dies are typically manufactured using precision machining techniques, such as milling, grinding, drilling, and electrical discharge machining (EDM). CNC machining centers and specialized equipment are used to fabricate the die components to tight tolerances and surface finish requirements. Heat treatment processes, such as quenching and tempering, are employed to enhance the hardness and durability of the die materials.