Description

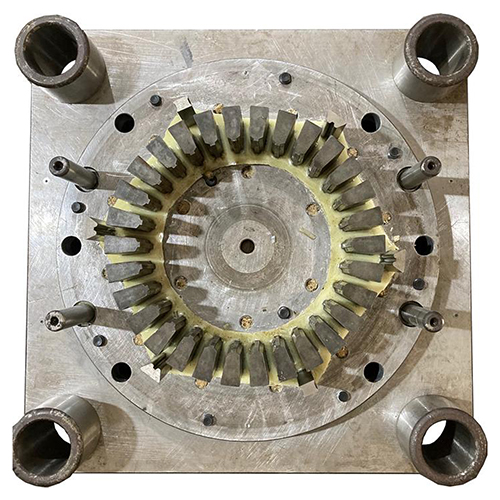

Electrical stamping, also known as electrical laminations or electrical steel stamping, refers to the process of shaping or cutting thin-gauge steel sheets into specific shapes and profiles for use in electrical equipment and devices. These stamped steel components, called laminations or cores, are integral parts of various electrical machines, transformers, motors, and generators. Electrical stamping plays a critical role in optimizing the performance, efficiency, and reliability of electrical systems. Here are some key aspects of electrical stamping:

Our range is customized on the following :

Precisely design

Material : Sheet Metal

Long operational life

Mould Runner: Hot Runner

Easy installation

Material Selection :

Electrical stamping typically utilizes thin-gauge steel sheets made from specialized electrical steel alloys. These alloys are designed to exhibit high magnetic permeability, low core losses, and minimal eddy current losses, making them ideal for use in electromagnetic devices. Common types of electrical steel include silicon steel (also known as electrical silicon steel or silicon steel), which contains silicon to enhance its magnetic properties.

Component Manufacturing :

Electrical stamping is used to produce laminations or cores, which are essential components of electrical machines and devices. Laminations are thin, flat sheets of steel with specific shapes and contours, while cores are assembled stacks of laminations bonded together to form the core structure. The stamping process shapes or cuts the steel sheets into precise shapes, slots, and profiles according to the design specifications of the electrical component.

Precision Machining :

Electrical stamping requires precision machining techniques to achieve tight tolerances, smooth surfaces, and consistent dimensions. CNC (computer numerical control) machining centers and specialized stamping equipment are used to fabricate the stamped components with high accuracy and repeatability. Advanced CAD/CAM (computer-aided design/computer-aided manufacturing) software is employed to create detailed die designs and tool paths, optimizing the stamping process for efficiency and quality.