Description

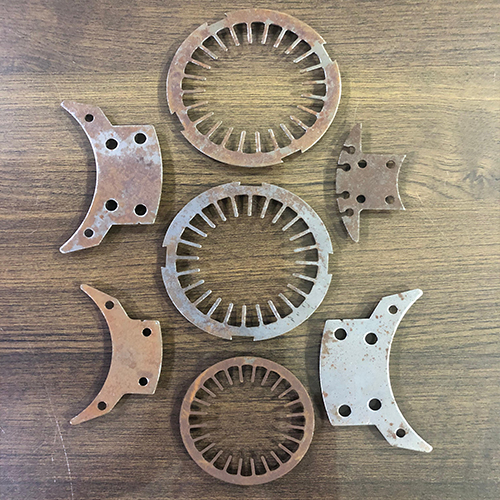

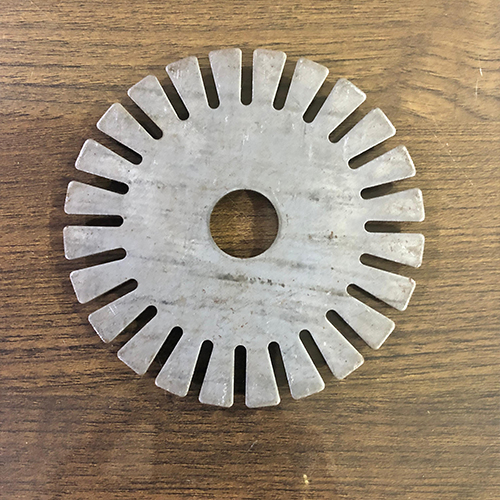

A sheet metal cutting die, also known simply as a cutting die or a blanking die, is a specialized tool used in metalworking processes to cut sheet metal into specific shapes and sizes with precision and consistency. This type of die is commonly employed in manufacturing environments to produce metal components for various applications across industries. Here are some key aspects of sheet metal cutting dies:

Our range is customized on the following :

Material : Stainless Steel

Surface Finishing : Chrome

Color : Silver

Features : Rust Proof

Corrosion Resistance : Yes

Design Considerations :

The design of a sheet metal cutting die is critical to achieving accurate and consistent results in the cutting process. The die is engineered to accommodate the desired part geometry, material thickness, tolerances, and production volume. Precision tooling and machining techniques are used to create sharp and durable cutting edges on the punches and dies, ensuring clean and precise cuts in the sheet metal.

Material Selection :

Sheet metal cutting dies are typically made from hardened tool steel or carbide materials chosen for their high hardness, wear resistance, and toughness. These materials can withstand the repeated stresses and pressures encountered during the cutting process and maintain their sharpness and cutting accuracy over prolonged use.

Automation and Efficiency :

In manufacturing environments, sheet metal cutting dies can be integrated into automated stamping or punching systems to achieve high-speed and efficient production. Automated feed mechanisms, such as roll feeders or servo-driven presses, are used to feed the sheet metal blanks into the die, while sensors and controls ensure precise positioning and alignment of the material. This automation helps improve productivity, reduce labor costs, and minimize material waste.