Description

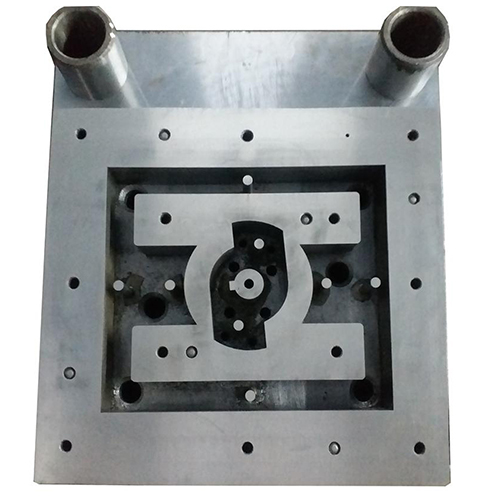

A motor stamping die is a specialized tool used in the manufacturing process of electric motors to shape or cut sheet metal into specific components or parts. Electric motors are ubiquitous in various applications, ranging from appliances and automotive systems to industrial machinery and consumer electronics. Motor stamping dies play a crucial role in the production of motor components such as laminations, cores, stators, and rotors. Here are some key aspects of motor stamping dies:

Our range is customized on the following :

Size : v-4 v-6 v-5 v-8

Material : Sheet Metal

Country of Origin : Made in India

Mould Runner: Hot Runner

Usage: Used In Automotive Industry

Component Manufacturing :

Motor stamping dies are used to manufacture critical components of electric motors, including laminations and cores. These components are typically made from thin-gauge electrical steel sheets (also known as laminations) that are stamped, cut, and stacked to form the motor's core structure. The precise shaping and cutting of laminations are essential for achieving optimal magnetic properties, efficiency, and performance in the motor.

Materials :

The material used in motor stamping dies is typically hardened tool steel or carbide, chosen for its high hardness, wear resistance, and toughness. The die material must withstand the repeated stresses and pressures encountered during the stamping process, as well as resist deformation and wear over time. Surface treatments or coatings may be applied to further enhance the die's durability and performance.

Die Design and Optimization :

The design of motor stamping dies is critical to achieving the desired component geometry, accuracy, and efficiency. Die designers use CAD software to create detailed die layouts, incorporating features such as punch profiles, die cavities, guiding mechanisms, and strip layouts. The goal is to optimize the die design for maximum material utilization, minimal waste, and high production throughput.