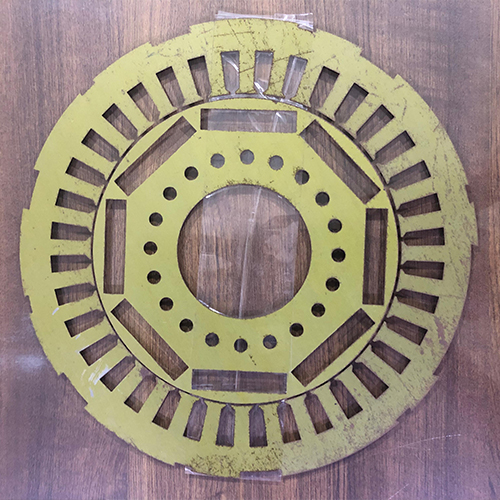

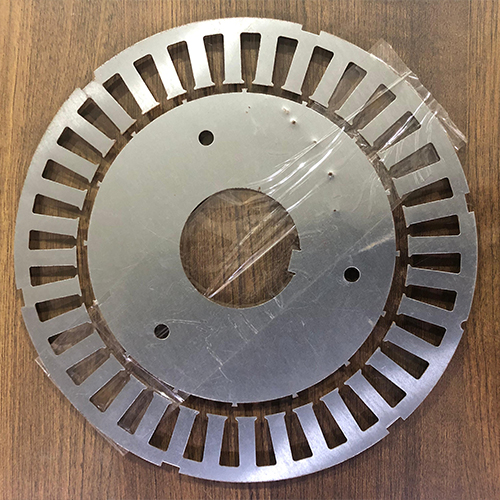

Description

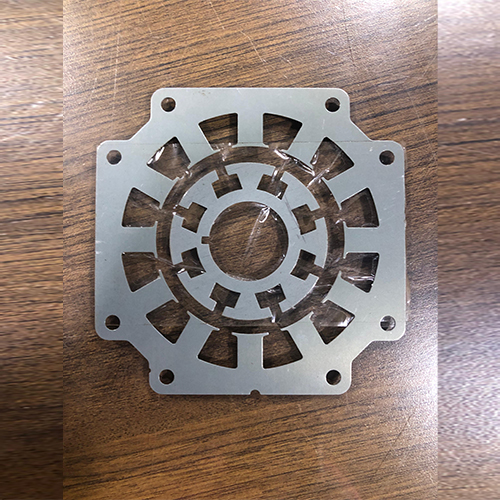

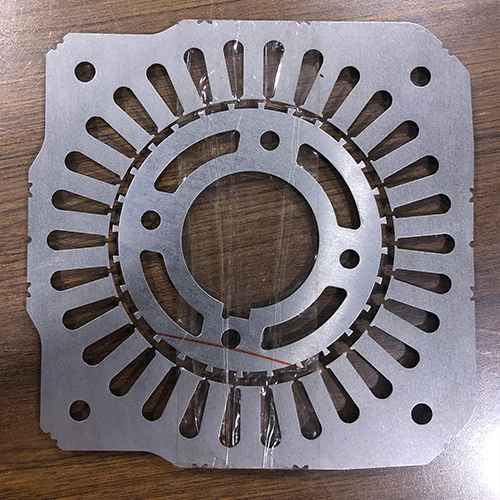

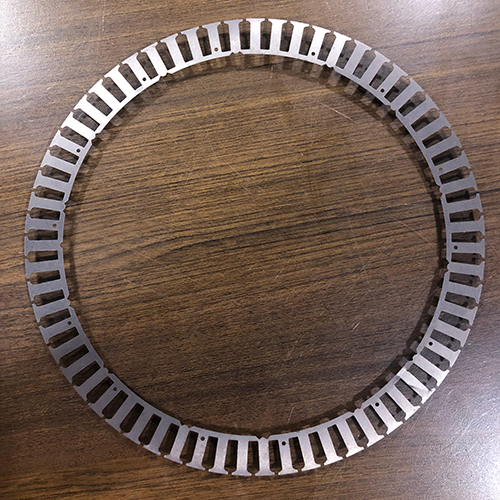

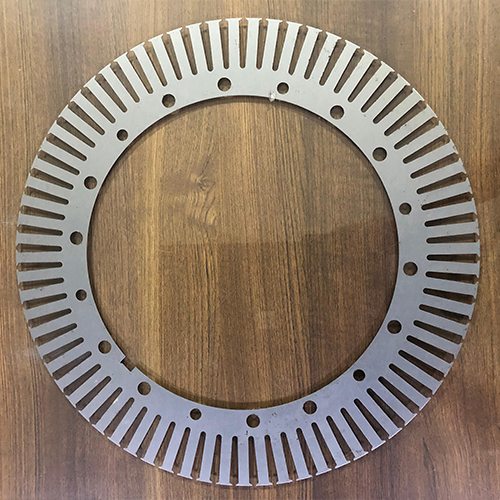

Electrical motor stamping, also known as motor core stamping or motor lamination stamping, is a specialized process used in the manufacturing of electric motors. This process involves shaping or cutting thin-gauge steel sheets, typically made from electrical steel alloys, into specific shapes and profiles to create the core components of electric motors. These core components include stator cores, rotor cores, and other laminated parts that are essential for the operation of the motor. Here are some key aspects of electrical motor stamping:

Our range is customized on the following :

Material : Stainless Steel

Material : Sheet Metal

Use For : Industrial

Thickness : 10-15 cm

Grade : SS306

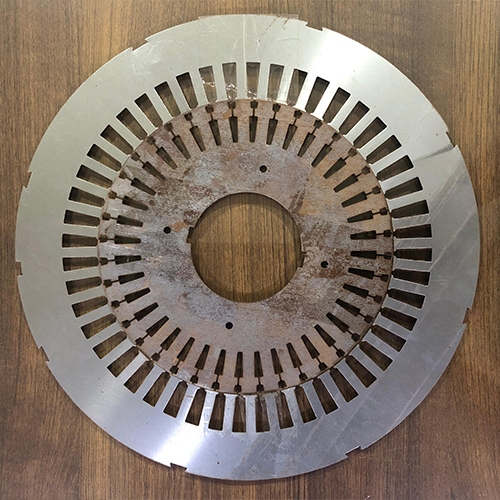

Material Selection :

Electrical motor stamping primarily utilizes thin-gauge steel sheets made from specialized electrical steel alloys. These alloys are chosen for their high magnetic permeability, low core losses, and minimal eddy current losses, which are crucial for optimizing the performance and efficiency of electric motors. Silicon steel (also known as electrical silicon steel or silicon steel) is a common material used for motor stamping due to its excellent magnetic properties.

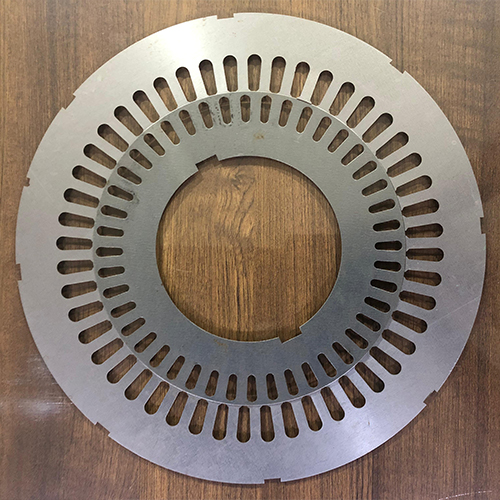

Component Manufacturing :

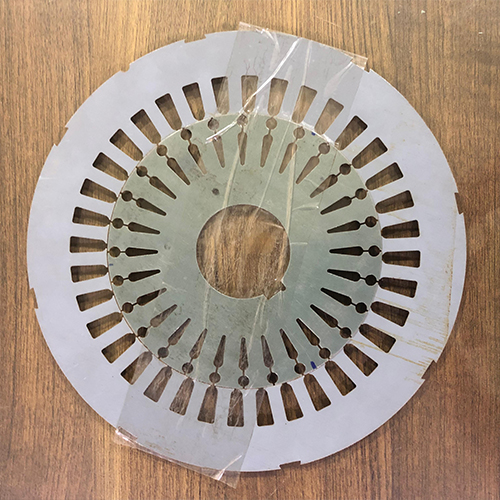

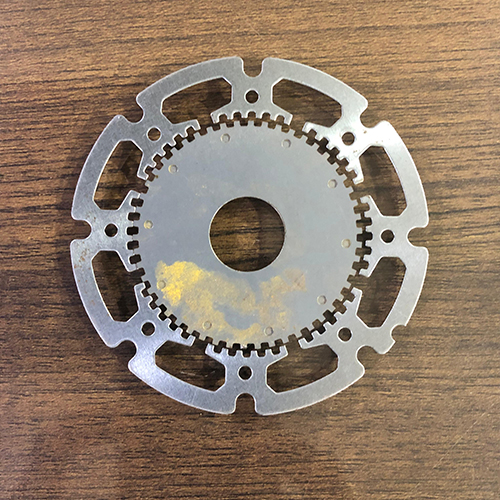

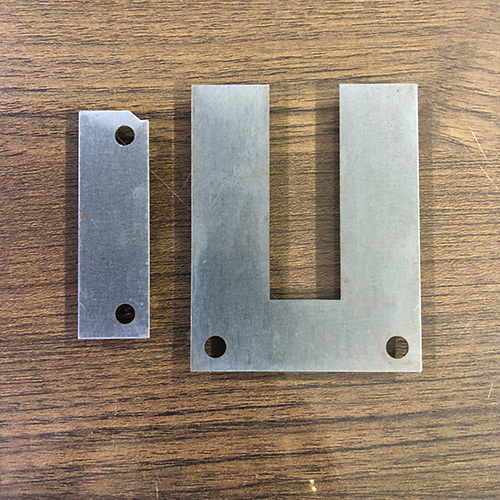

Electrical motor stamping is used to produce core components such as stator cores and rotor cores, which are integral parts of electric motors. Stator cores are stationary components that house the motor windings and create the magnetic field, while rotor cores are rotating components that interact with the stator to produce mechanical motion. The stamping process shapes or cuts the steel sheets into precise shapes, slots, and profiles according to the design specifications of the motor.

Stamping Process :

The stamping process is typically performed using specialized stamping presses equipped with dies and punches designed for specific motor components. The steel sheets are fed into the press, where they undergo various stamping operations to shape, cut, and form the material into the desired configurations. Precision machining techniques, such as CNC (computer numerical control) machining, may be used to achieve tight tolerances and consistent dimensions.